CX-9900 MOBILE METAL ANALYZER

CX-9900 mobile metal analyzer is a mobile arc spark spectrometer ideal for many applications in the metal producing, processing, and recycling industries. CX-9900 mobile metal analyzer has advantages of high precision and good stability of analysis, easily operation, and extensive applications, small size, light in weight. CX-9900 mobile analyzer can be used in identification of materials in processing factory, structure material analysis in petrochemical equipment, and metal analysis in recycling industry.

CX-9900 mobile spectrometer is metal analyzer with CCD optical technology and modern microelectronics components.

CX-9900 mobile spectrometer is your choice for analysis of C, P, S, B, Sn, As and N and other non-metallic elements and other metal contents in inconvenient cutting large Metal components. It can analyze various forms of metal materials, such as: pipe, bar, valves, welds, tanks, castings and so on. The CX-9900 Mobile Spectrometer can meet your analytical requirements, whether in the factory premises or outside the factory, in scrap yards, submerged submarine tanks, or on high-altitude ladders in chemical plants.

1. Europe Technology was introduced, first manufacturer of mobile metal analyzer in China, Break the technological monopoly, small volume, light-weight

2. Applied with CCD optical technology and modern microelectronic components; it is the best choice for the analysis of non-metallic elements such as C, P, S, B, Sn, As in those large metal components which are not easy to cut.

3. Can analyze all kinds of metal materials

4. Improved optical system makes it suitable for analysis needs under various circumstances, no matter outside or high altitude. High accuracy and stability.

5. Integrated design, portable, can be divided for transportation

6. Battery pack can be used for CCD, hundreds of excitation for once charge

7. Typical Pashce-Runge Structure

8. Core parts are from top global suppliers, ensure the optical performance

9. HEPS digital spark light source improves the stability of discharging, ensures the analysis accuracy.

10. High-end ARM processor, high-speed data collection and process synchronously, only 20 seconds is needed for one analysis

11. Optimized data stability and good data consistency for analysis in different periods.

12. It is free to extend curves, change or add channel in same matrix. Hard configuration is not needed for adding new matrix, free technical support and software update

13. Simple and elegant outlook design, optimized property, cost-effective, low energy consumption

14. Focus on customer requirements, offer in-time after-sale service

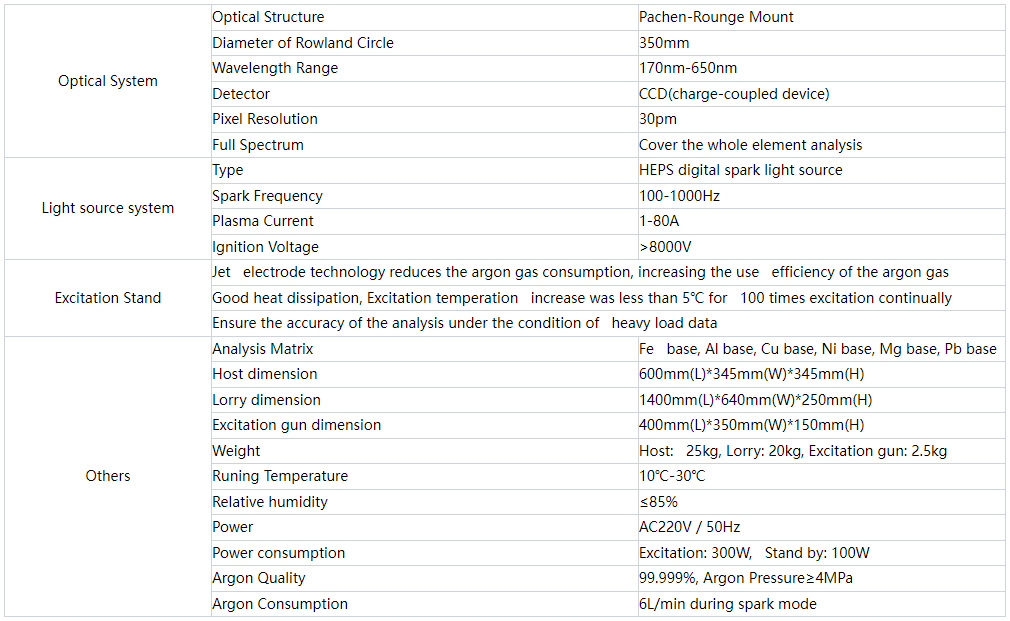

Optical System

Optical Structure

Pachen-Rounge Mount

Diameter of Rowland Circle

350mm

Wavelength Range

170nm-650nm

Detector

CCD(charge-coupled device)

Pixel Resolution

30pm

Full Spectrum

Cover the whole element analysis

Light source system

Type

HEPS digital spark light source

Spark Frequency

100-1000Hz

Plasma Current

1-80A

Ignition Voltage

>8000V

Excitation Stand

Jet electrode technology reduces the argon gas consumption, increasing the use efficiency of the argon gas

Good heat dissipation, Excitation temperation increase was less than 5℃ for 100 times excitation continually

Ensure the accuracy of the analysis under the condition of heavy load data

Others

Analysis Matrix

Fe base, Al base, Cu base, Ni base, Mg base, Pb base

Host dimension

600mm(L)*345mm(W)*345mm(H)

Lorry dimension

1400mm(L)*640mm(W)*250mm(H)

Excitation gun dimension

400mm(L)*350mm(W)*150mm(H)

Weight

Host: 25kg, Lorry: 20kg, Excitation gun: 2.5kg

Runing Temperature

10℃-30℃

Relative humidity

≤85%

Power

AC220V / 50Hz

Power consumption

Excitation: 300W, Stand by: 100W

Argon Quality

99.999%, Argon Pressure≥4MPa

Argon Consumption

6L/min during spark mode

In the fields of Metallurgy, casting, machining, automobile manufacture, aerospace, weapons, metal processing, production technology control, furnace tests, laboratory inspection